Engine Inoperative Principles in a Twin Airplane

6 min read

Single-engine and multiengine airplanes behave very differently in the event of a single-engine failure.

This is the main reason the FAA requires separate ratings on your pilot certificate for multi- and single-engine aircraft.

Following an in-flight engine failure on a single-engine airplane, the pilot has only one opportunity to land within gliding distance.

Adding one or more engines for redundancy would seem like a natural solution to this problem. If an engine fails on a twin, the remaining one should help you fly safely to the nearest airport. And in fact, multiengine aircraft do add a layer of safety in the event of power loss. However, too many accidents occurred on light twin aircraft following an engine failure, even when the other worked fine. The culprit is the asymmetrical thrust produced by most multiengine airplanes. This force imbalance causes a significant loss of directional control and performance. For a light twin, an engine failure on takeoff may result in an 80 percent loss of climb performance and severe yaw and rolling tendencies toward the failed engine.

In this article, I'll address the principles of flying a multiengine airplane when one of its engines fails.

Side-Slip vs Zero Side-Slip

- With all engines operating, you eliminate sideslip by keeping the inclinometer's ball centered, just like you do in a single-engine airplane. This condition is called zero-sideslip, in which the aircraft presents the smallest profile to the relative wind, producing minimum drag.

- A centered ball is no longer an indication of zero-sideslip after one engine fails due to the asymmetric thrust.

- Even with the ball centered, an airplane producing asymmetrical thrust is still in a side slip due to the lateral force created by the rudder.

- There is no conventional equipment to display zero-sideslip in the cockpit. However, a simple yaw string can be attached to the windshield to make it visible.

- To achieve zero side slip with one engine inoperative, you need to use both rudder and aileron controls.

Using the rudder, place 1/2-1/3 of the ball outside its cage towards the operating engine. For roll, apply about 2° of bank with the ailerons towards the operative engine. The opposing forces of the horizontal component of lift and rudder side force will eliminate the sideslip. - These mnemonics may help you remember the correct control technique:

- "Raise the dead engine" for aileron control. Apply ailerons towards the functioning engine.

- "Live foot, live engine," or "dead foot, dead engine" for rudder control.

- Zero-side slip will give us the best performance and directional control.

- Since asymmetrical thrust is the cause of loss of directional control, reducing power will help with directional control but will decrease performance. Similarly, adding power will reduce directional control but increase performance.

- In a one engine failure condition, a typical light twin loses about 80% of its climb performance due to the increased drag and decreased excess power required for a climb.

Critical Engine

The critical engine is the engine whose failure would most adversely affect the performance or handling qualities of the airplane. (FAR 1.1). On a conventional light twin, both propellers rotate clockwise (from the pilot's point of view). This makes the left engine critical.Four factors are responsible for making the left engine critical on a conventional twin:

- P-Factor (asymmetric thrust)

- Accelerated slipstream

- Spiraling slipstream

- Torque

Counter-Rotating Engines

Aircraft manufacturers solved the critical engine problem by implementing counter-rotating propellers, where the right engine rotates counter-clockwise.

In this configuration, losing either engine would have the same effect on performance and handling, and therefore there is no critical engine.

P-Factor

With high angles-of-attack, the descending blade (right side) produces more thrust than the ascending blade (left).

The descending, right blade on the right engine has a longer arm from the CG than the descending (right) blade of the left engine, creating a yaw force to the left.

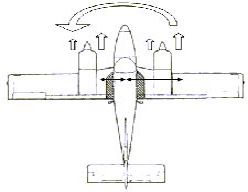

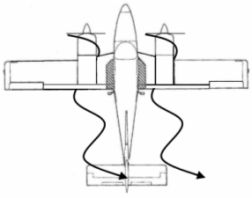

P-Factor conventional-rotating engines

In a conventional twin, P-factor shifts both engines' center-of-thrust to the right, resulting in a significant left yawing tendency. The distance (arm) between the center of thrust to the center of the aircraft's CG is greater on the right engine than on the left engine. Therefore, a failure of the left engine will result in a more severe yawing tendency than the failure of the right engine..

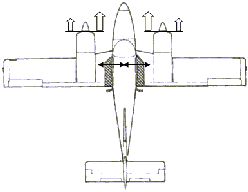

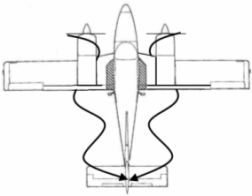

P-Factor counter-rotating engines

In a counter-rotating twin, P-factor shifts the center of thrust closer to the aircraft's CG. Failure of either the left or right engine will cause the same amount of directional loss of control.Accelerated Slipstream

Accelerated slipstream is a rolling tendency resulting from P-factor.

The wing generates more lift directly behind the propellers then in other areas due to increased airflow from prop wash.

Since P-factor shifts the center-of-thrust towards the descending blade, it also shifts propwash and, as a result, lift by the same distance.

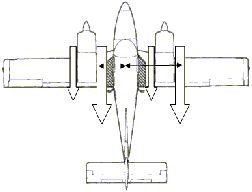

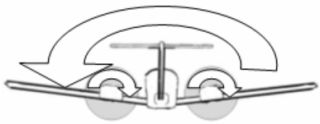

Accelerated Slipstream - Conventional Twin

As a result of P-factor, a stronger induced lift is produced on the right propeller's right side than on the left side of the left propeller by prop wash. A left engine failure will shift the center of lift far to the right, which results in a strong left rolling moment.Accelerated slipstream may also affect pitch. When the left engine fails, less negative lift is produced by the horizontal stabilizer, resulting in a pitch down moment.

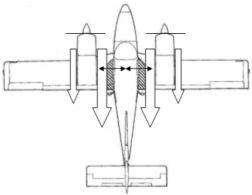

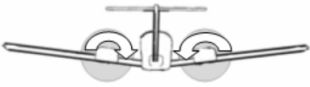

Accelerated Slipstream - Counter-Rotating Engines.

Failure of either engines will result in the same amount of sideward shift of center of lift. It will also be less severe than it would be on a conventional twin's critical engine failure, since P-factor brings the center of lift closer to the CG of the aircraft on both wings.Spiraling Slipstream

Spiraling slipstream is the prop wash rotating in a corkscrew pattern towards the back of the airplane. When it hits the tail from the side, it creates a yawing tendency.

Spiraling slipstream – Conventional Twin

For a right engine failure, the slipstream from the left engine would hit the tail on the left and oppose the right asymmetrical thrust. This results in better directional control.In the event of a left engine failure, the spiraling slipstream created by the right engine will not hit the tail and would not contract the asymmetrical thrust. Therefore the left engine is critical.

Spiraling slipstream - Counter-Rotating Engines.

In the event of either engine failure, the spiraling slipstream hitting the tail, would oppose asymmetrical thrust and help the pilot with directional control.Torque

For every action, there is an opposite and equal reaction (Newton's 3rd law of motion).

Torque is a turning force applied on the aircraft by the rotation of the propeller. A clockwise-spinning propeller will apply in a counter-clockwise force on the airplane.

Torque – Conventional Twin

The clockwise rotation of both engines on a conventional twin creates a left rolling tendency. If the right engine fails, this left rolling tendency will oppose the right roll force created by the asymmetrical thrust and help the pilot maintain control.

However, if the left engine fails, torque's left rolling tendency will add to the left asymmetric thrust, making it much more difficult to maintain directional control. This makes the left engine critical.

Torque - Counter-Rotating Engines

With a counter-rotating twin airplane, no matter which engine fails, torque opposes the roll created by asymmetric thrust.

VMC

VMC is the calibrated airspeed at which, when the critical engine is suddenly made inoperative, it is possible to maintain control of the airplane with that engine still inoperative, and thereafter maintain straight flight at the same speed with an angle of bank of not more than 5 degrees. The method used to simulate critical engine failure must represent the most critical mode of powerplant failure expected in service with respect to controllability. (FAR 23.149)

- Published VMC is marked as a red line on the airspeed indicator.

- Actual VMC changes with different factors, while published VMC remains the same.

- Published VMC is close to the worst case scenario, actual VMC may be lower, especially after feathering the inoperative engine’s propeller. Don’t bet your life on that fact, Vmc may be higher than you assume it is.

- VMC, as defined by 23.149 must not exceed 1.2 VS1.

- VSSE is the Single engine safety speed. This speed is slightly higher than published VMC and creates a safety buffer from VMC for intentional engine out operations. You should never fly the airplane below VMC or VSSE, if published, under single-engine operations.

- Why is directional control affected by airspeed?

The faster the airspeed the more force the rudder can produce to resist the yawing tendency caused by asymmetrical thrust.

Conditions considered by the manufacturer for determining VMC speeds (FAR 23.149, Airplane Flying Handbook)

- Standard atmosphere. (FAR 23.45)

- Most unfavorable CG and weight.

- Out of ground effect.

- Critical engine INOP

- Bank no more than 5° towards operating engine.

- Max available takeoff power on each engine initially

- Trimmed for takeoff.

- Wing flaps set to takeoff position.

- Cowl flaps set to takeoff position.

- Landing gear retracted.

- All propeller controls in takeoff position. (INOP engine windmilling)

- Rudder force required by the pilot to maintain control must not exceed 150 pounds.

- It must be possible to maintain heading ±°20.

Factors that affect VMC

| Factor | VMC | Performance |

|---|---|---|

| Increase in density altitude | 😃 Decreases (good) | 🙁 Decreases (bad) |

| Increase in weight | 😃 Decreases (good) | 🙁 Decreases (bad) |

| Windmilling prop (vs. feathered) | 🙁 Increases (bad) | 🙁 Decreases (bad) |

| Aft CG | 🙁 Increases (bad) | 😃 Increases (good) |

| Flaps extended | 😃 Decreases (good) | 🙁 Decreases (bad) |

| Gear retracted | 🙁 Increases (bad) | 😃 Increases (good) |

| Up to 5° Bank towards good | 😃 Decreases (good) | 😃 increases (good) |

Recommended Reading

Last Updated:

This post may contain affiliate links or advertisements. This means I earn a small commision if you decide to make a purchase through the links at no extra cost to you.